Methods of IP Protection for Flexible LED Strips

- Sep 10, 2025

- 4 min read

Updated: Oct 22, 2025

Understanding how to protect LED strips against dust and moisture for every application

Flexible LED strips are widely used in industrial, architectural, residential or commercial lighting. Being ideal for a range of installations—from outdoor façades to marine applications, they are exposed to a many different environmental factors that determines the level of protection needed. This is where Ingress Protection (IP) ratings come into play.

The IP rating is an international standard that classifies the degree of protection against solids (like dust) and liquids (like water).

Choosing the Right IP Rating

When selecting LED strips, consider the environment:

• Dry, indoor use → IP20

• Humid or semi-protected → IP54 or IP65

• Outdoor rain-exposed → IP65 or IP67

• Submersion → IP67 or IP68

Flexible LED strips are manufactured with different methods of sealing and encapsulation to achieve these ratings. Below we explore the most common methods of providing IP protection and what they mean in practice.

1. Silicone or Epoxy Coating (IP54 / IP65)

A thin layer of silicone or epoxy resin is applied over the LED strip to shield it from dust and splashing water. This method is lightweight and cost-effective while preserving the strip’s flexibility.

Typical IP rating: IP54 (basic splash resistance) or IP65 (dust-tight, protected against water jets).

Applications: Kitchens, bathrooms, outdoor signage under eaves, or places exposed to humidity but not direct water immersion.

Advantages | Disadvantages |

Lightweight and maintains good flexibility. | 10-20% negative impact on LED optical properties (Luminous Flux, Color Temperature) |

Inexpensive compared to more advanced methods | Protection is limited—only splash and jet resistant, not immersion-proof. |

Offers sufficient protection for indoor damp areas or semi-outdoor use. | Over time, epoxy may yellow or crack due to UV exposure |

Simple manufacturing process → good availability | Silicone coatings can sometimes peel or separate from the PCB in harsh conditions |

2. Silicone Tubing (IP65 / IP67)

The LED strip is placed inside a hollow silicone tube. This provides a higher degree of water resistance while allowing the strip to remain flexible. The tube is often sealed at the ends with silicone caps and adhesive to prevent water ingress.

Typical IP rating: IP65 (resistant to jets of water) or IP67 (resistant to temporary immersion up to 1 meter).

Applications: Outdoor terraces, garden lighting, poolside areas, or outdoor signage exposed to rain.

Advantages | Disadvantages |

Flexible and easy to install | 10-15% negative impact on LED optical properties (Luminous Flux, Color Temperature) |

Better mechanical protection against bending, dust, and water ingress | Slightly bulkier compared to coated strips |

Can be resealed if cut (using additional end caps and silicone glue) | Heat dissipation is weaker (LEDs can run hotter) |

Often clearer and less prone to yellowing than epoxy | Requires proper sealing at both ends—installation errors may reduce protection |

3. Extrusion in Solid Silicone (IP67 / IP68)

For increased durability, the LED strip can be completely encased in solid or semi-solid silicone through an extrusion process. This method offers excellent protection against dust, water, and even UV exposure, which prevents yellowing over time.

Typical IP rating: IP67 (temporary immersion) or IP68 (continuous immersion, usually specified by the manufacturer for depth and time).

Applications: Pools, fountains, aquariums, marine environments, or outdoor installations in harsh climates.

Advantages | Disadvantages |

Excellent protection against dust, water, and UV radiation | 15-20% negative impact on LED optical properties (Luminous Flux) |

Long-lasting, resistant to yellowing and cracking | More expensive than coating or tubing |

Superior durability for outdoor and underwater environments | Heat dissipation can still be limited if not designed with thermal considerations |

Provides good diffusion of light (often eliminating visible LED dots) | Cutting requires specialized sealing kits to maintain IP rating |

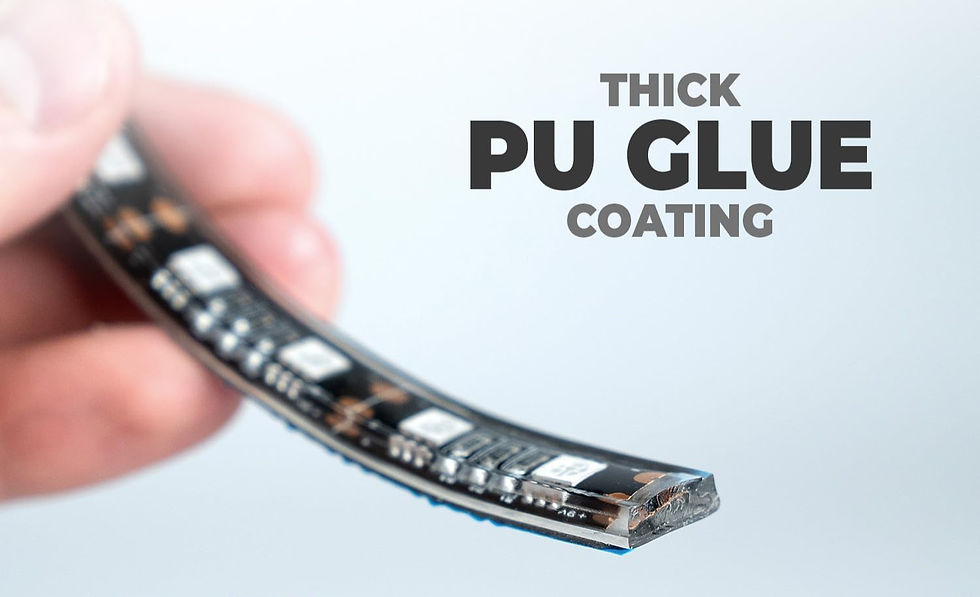

4. PU (Polyurethane) Encapsulation (IP65 / IP67)

Polyurethane is used as an alternative to silicone, offering strong protection with better resistance to chemicals and yellowing from UV light. It is often preferred in outdoor and industrial applications where durability is critical.

Typical IP rating: IP65 (resistant to jets of water) or IP68 (continuous immersion, usually specified by the project requirements for depth and time).

Applications: Outdoor terraces, garden lighting, poolside areas, or outdoor signage exposed to rain.

Advantages | Disadvantages |

Better resistance to UV radiation and yellowing than silicone or epoxy | 5-15% negative impact on LED optical properties (Luminous Flux and CCT) |

Strong mechanical protection—resistant to impact and abrasion | More expensive than coating or tubing |

Suitable for harsh outdoor environments and industrial applications | Heat dissipation is limited if not designed with thermal considerations |

Maintains flexibility compared to solid silicone extrusion | Cutting and re-sealing is more difficult than with tubing |

4. LumProtect Lamination (IP67/IP68)

LumProtect is an innovative lamination process developed by Lumistrips / Lumitronix that fully encapsulates flexible LED strips, modules or sheets with ultra-thin polymer layers—both front and back—using heat and pressure. This achieves:

Typical IP rating: IP67 (resistant to jets of water) or IP68 (resistant to temporary immersion up to 1 meter).

Applications: demanding projects for architectural and outdoor lighting on façades, bridges, gardens, and public spaces, industrial environments, healthcare applications.

Advantages | Disadvantages |

Strong protection against dust, water, UV, and chemicals | 1-5% negative impact on LED optical properties (Luminous Flux and CCT) |

High transparency (92–94%) with minimal color shift | More expensive than coating or tubing |

Durable, abrasion-resistant, long-lasting | Cutting and resealing requires care |

Can be applied also to large LED modules or sheets | Only for custom-made projects |

Effect of IP Protection on Light Output and Color Quality for White LEDs

A clear comparison table showing how each IP protection method affects luminous flux and color temperature stability of white LED strips:

Method | Typical Flux Reduction | Color Temperature Shift | Long-Term Stability |

Silicone / Epoxy Coating | ~10–20% | Silicone: visible warm shift (100–200 K) Epoxy: visible warm shift (100–300 K) | Moderate – epoxy prone to yellowing, silicone may peel |

Silicone Tubing | ~10–15% | Visible warm shift (50–150 K) | Good, but condensation or dirt inside tube reduces performance |

Solid Silicone Extrusion | ~15–20% | Visible warm shift (100–200 K) | High durability, good UV stability; maintains CCT well |

PU (Polyurethane) Encapsulation | ~10–15% | Slight warm shift (50–100 K) | Excellent – resists UV yellowing and chemical exposure |

LumProtect Lamination | ~3–5% | Smallest warm shift (10–50 K) | Outstanding – UV, chemical, and aging resistant |

Discover the Difference with LumProtect™

When it comes to long-lasting, high-quality lighting, choosing the right protection makes all the difference. Our German-made flexible LED strips with LumProtect™ technology combine durability, flexibility, and unmatched light quality—perfect for projects that demand both performance and reliability.

Comments